For over 30 years, Cyber-Fab has been a trusted provider of metalworking services to an array of industries that include electronics, aerospace, automotive, defense, robotics, and more. We manufacture small to medium quantities using advanced technology such as CNC punching, bending, laser cutting, and robotic welding. Our factory is ISO 9001:2015 certified and AS9100 Rev. D registered to ensure the utmost quality in all our processes.

Customers of Cyber-Fab benefit from our competitive lights-out manufacturing capabilities. Our fully automated production facility utilizes multiple high-tech machines that require minimal human interaction. The cost-effective process allows high repeatability, precision, and speed compared to traditional manufacturing methods.

Learn more about the features, benefits, and real-life applications of lights-out manufacturing.

Overview of Lights-Out Manufacturing & Examples

Also called a dark factory, a lights-out factory is a manufacturing facility that runs 24/7, maintaining productivity without human involvement and, hence, when the lights are out. For the system to be effective, every operation must be automated and precisely controlled without sacrificing quality.

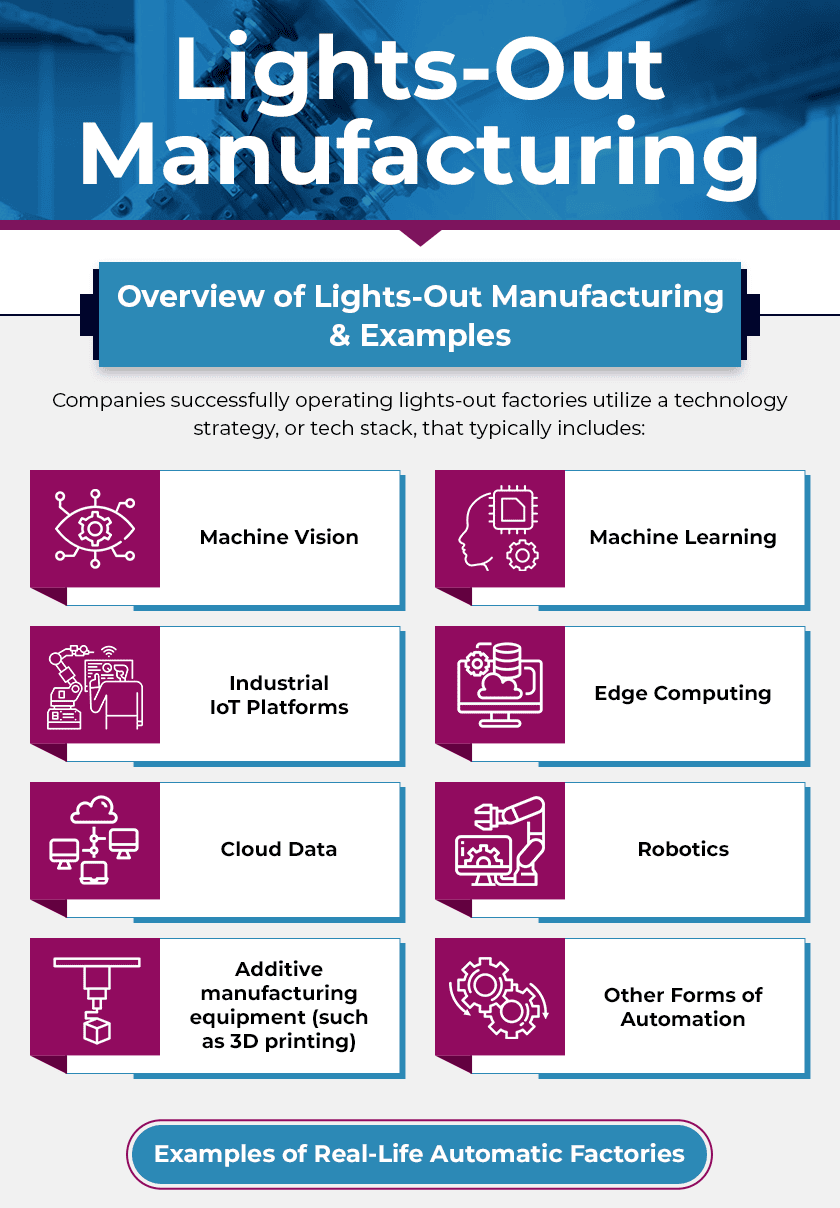

Companies successfully operating lights-out factories utilize a technology strategy, or tech stack, that typically includes:

- Machine vision

- Machine learning

- Additive manufacturing equipment (such as 3D printing)

- Industrial IoT platforms

- Edge computing

- Cloud data

- Robotics

- Other forms of automation

Examples of Real-Life Automatic Factories

These are some real-world examples of fully automated lights-out manufacturing facilities.

- FANUC: One of the first companies to embrace a lights-out manufacturing culture, FANUC is a Japanese tech leader that produces robots to perform monotonous tasks that are often dangerous to humans. Their robots paint and assemble automobiles, manufacture injection-molded electrical parts, sort packaged items, and more. The $50 billion company is a world leader in factory automation and an innovator of lights-out technology, helping companies worldwide realize the benefits of lower utility costs, fewer workplace injuries, and faster, more accurate production.

- Amazon: The technology and retail giant uses robotic systems on a large scale in its distribution centers, with little to no human intervention required.

- Philips: The electronics company known for producing electric razors employs fewer than 12 employees in its Netherlands manufacturing facility, while 128 robots handle daily operations. The human workers are merely on standby for quality assurance.

Advantages of Lights-Out Manufacturing

With industrial robots operating the entire facility, companies can experience the following benefits.

Reduced Production Costs

A limited workforce equates to a reduction or total elimination of total worker salaries. Companies enjoy reduced utility bills since robots do not require climate-controlled environments or factory lighting. Using robots eliminates material costs and production delays that result from human error.

Enhanced Workplace Safety

Relying on automated machinery means lights-out manufacturing is significantly safer for the few human workers who do work onsite. Robots are not only resilient in adverse conditions but can also remain fully operational in situations that could be dangerous for human workers, such as those involving hazardous materials and sharp objects.

Increased Productivity

Human workers cannot keep pace with robots. Automated technology allows the robots to work at faster speeds 24/7, exceeding the capabilities of several human workers combined. An entire workforce of robots, compared to humans, dramatically increases overall productivity.

Reduced Carbon Footprint

Lights-out production reduces energy consumption associated with keeping lights and climate control settings on for human workers. Compared to traditional manufacturing facilities, robots eliminate carbon emissions, are energy-efficient, and offer a sustainable, long-term manufacturing method. Material waste and scrap caused by human error are eliminated with the precision of robot interfaces.

Greater Product Consistency

The accuracy of robots in a lights-out environment improves product quality. The machines can be programmed with specific instructions for each production run, ensuring product consistency and repeatability. Unlike humans, robots are never distracted and can create quality products every time.

Advanced Maintenance

Machines are not infallible—tools may wear down or break, requiring maintenance. With automation technology, operators in charge of lights-out facilities can remotely monitor equipment for abnormalities or indicators of a future breakdown. High-frequency data adapters collect data from robots and can inform both prescriptive and predictive maintenance.

Considerations When Selecting a Lights-Out Partner

Recent labor shortages, supply chain disruptions, and factory shutdowns have made lights-out manufacturing an appealing option for many businesses. The ability to keep production going around the clock is becoming more popular as manufacturers across industries demand the benefits of robotic technology.

When selecting a lights-out partner, there are several things to consider, such as:

- Equipment performance: Reliability of machinery is a primary concern when there are no workers available to provide necessary maintenance, perform interventions, adjust operational parameters, or tweak the equipment as needed. The right partner should offer state-of-the-art technology able to handle the intense nature of lights-out production.

- Equipment capabilities: The manufacturing equipment needs to provide continuous operation without slowdowns. It needs to be stable and dependable, with sufficient power to perform operations throughout the day. The machines must be capable of automatic corrections or come with remote solutions for common issues, such as overheating.

- Preventative maintenance: It is imperative to verify a routine maintenance program is in place, regardless of the chosen manufacturing method. If operators are not in the factory, there needs to be sufficient protocol for getting repair assistance or notifying management of potential issues. A reliable service provider is necessary to keep production running smoothly.

- Management and staff commitment: Management support is essential in keeping lights-out automated programs operational. Support staff must buy into the robotic systems for effective performance. While most changes are met with fear or trepidation, ensure employees understand the importance of how they will contribute to the program’s success.

Lights-Out Manufacturing With Cyber-Fab

For more than 30 years, Cyber-Fab has provided innovative metal fabrication solutions to a range of industries including the defense, aerospace, and electronics markets. Our fully automated lights-out manufacturing process enables us to minimize costs and provide unparalleled quality to our customers.

We offer a suite of metal fabrication capabilities, including design support and engineering services. Our experienced staff collaborates with clients from initial project conception to manufacturing to delivery. Our lights-out capabilities produce high-quality components for specific applications at competitive prices. Contact us today or request a quote to discuss your business needs.