At Cyber-Fab, our combined expertise and resources enable us to provide our customers with superior metal fabrication services, which include CNC laser cutting, bending, punching, spot welding, arc welding, and automated welding.

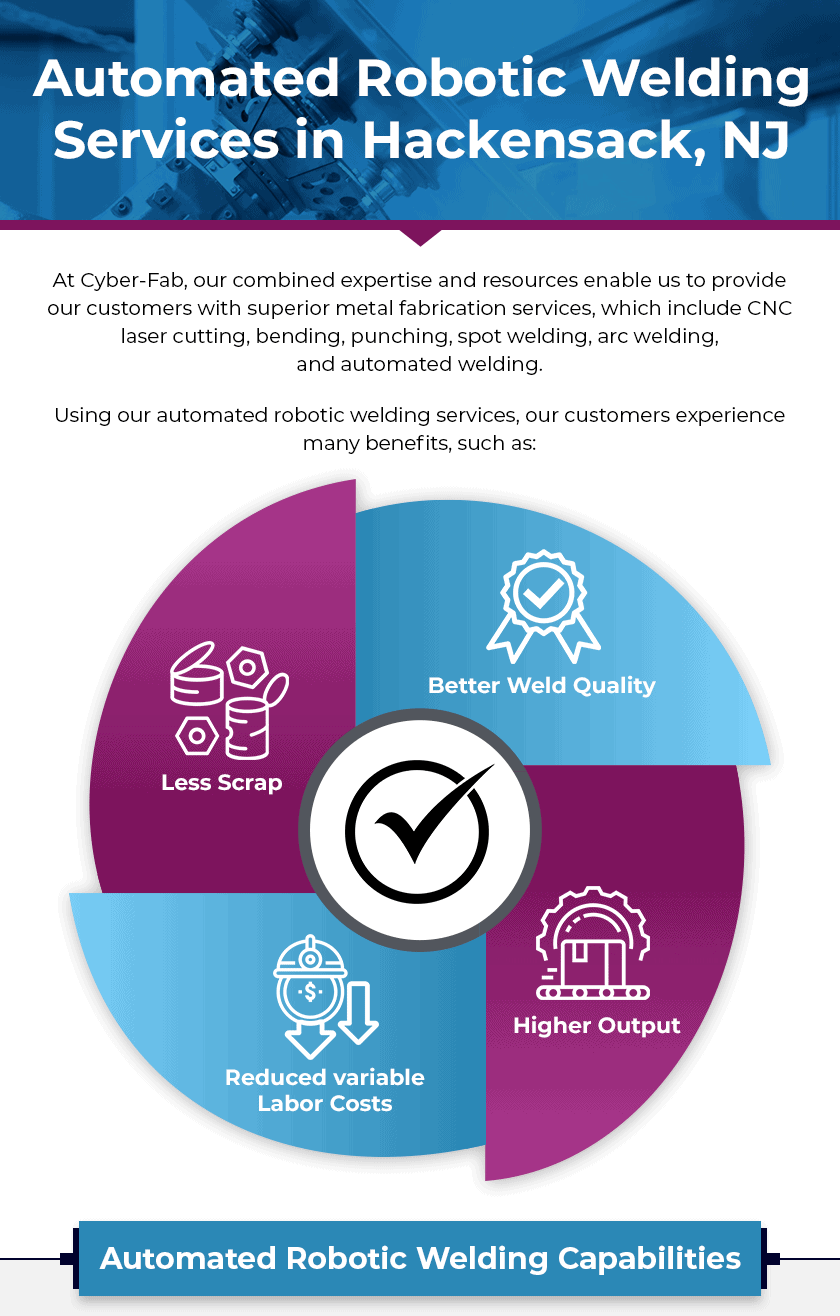

Using our automated robotic welding services, our customers experience many benefits, such as:

- Better weld quality

- Higher output

- Less scrap

- Reduced variable labor costs

We offer services for customers across a wide range of industries, including the Internet of Things, aerospace, defense, navigation, robotics, autonomous vehicle, and other industries requiring reliable metalworking suppliers.

Automated Robotic Welding Capabilities

At Cyber-Fab, we use a variety of robotic welder systems, materials, and processes.

Equipment

We use these two types of automated welders:

- Motoman Arc World Robotic Welding Cell

- Motoman Robotic Cell With Fronius Power Supply

Materials Used

We work with a variety of materials, such as:

- Stainless steel

- Aluminum

- Carbon steel

Arc Welding

Tungsten inert gas (TIG) welding is a process that uses a tungsten electrode, a filler material, and an inert shielding gas to create high-quality welds. TIG welding is especially well-suited for thin substrates and is usually done by highly skilled welders. We provide manual and robotic TIG welding certified to AWS D17.1 and AWS D1.2. Our CNC LC2012C1 has laser and punching in the same machine to eliminate the need for special tooling.

Spot Welding

This welding method welds overlapping metal sheets of thicknesses up to 3 mm. The process uses two electrodes at the same time to clamp together the metal sheets and pass a current through them. Spot welding offers certain benefits, including the elimination of filler materials, efficient energy use, and limited deformation of workpieces. However, the reduced weld strength of this process makes it applicable only to certain ferrous metals.

Our spot welding service is MIL-W-6858D certified.

Applications

Cyber-Fab serves customers across a range of industries with automated welding capabilities.

IoT

The Internet of Things (IoT) industry continues to further the development of connected devices of all types, from kitchen appliances and smartphones to industrial equipment and cargo trackers. The industry has expanded over the years as businesses strive to provide critical software and hardware for use in autonomous vehicles, smart devices, aerospace equipment, and more.

Our welding and other services can help manufacture a variety of customized components for nearly any IoT application.

Autonomous Vehicles

Cyber-Fab helps original equipment manufacturers (OEMs) develop autonomous vehicle (AV) technology. We provide dependable robotic welding services along with engineering, regulatory compliance, design, and metalworking capabilities such as lights-out manufacturing. These capabilities allow us to supply end-to-end production of custom parts.

While AV development primarily focuses on consumer vehicles and commercial freight vehicles, Cyber-Fab also offers support for military and government projects. Regardless of your AV application, we can provide you with high-quality customized parts.

Robotics

Automation allows American companies to easily reshore operations and shorten their supply chains. For example, manufacturing robots that handle repetitive tasks free up human workers to perform more complex tasks and prevent stress injuries. Collaborative robots working in warehouses can assist with packing and picking operations, streamlining the efficiency of warehouse associates.

At Cyber-Fab, we specialize in manufacturing various industrial robots to support the growth of this industry.

Aerospace & Defense

Aerospace manufacturers rely on high-performance parts to construct spacecraft and aircraft. These types of equipment often function under extreme environmental conditions, so manufacturers must adhere to strict quality assurance standards. Components used in the defense industry must also adhere to strict standards to prevent failure upon deployment.

At Cyber-Fab, we have the resources and experience needed to meet stringent aerospace and defense project requirements. Some of the products we develop for these industries include:

- Chassis

- Brackets

- Heat exchangers

- Enclosures

New Jersey Robotic Welders

The experts at Cyber-Fab can help develop parts, components, and systems for use in diverse industries and applications. We adhere to all relevant industry standards to ensure your products meet the intended application’s requirements.

Contact us today to learn more about our welding capabilities, or request a quote to get started on your next project.